|

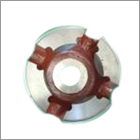

Offering an extensive

range of S. G. Iron Castings In various Grade.

An Overview

The sound

infrastructure base and a team of experts have enabled Monark Steels

to efficiently serve the market for over 12 years. Established in the

year 1997 under the able guidance of Mr. S. S. Patil, we have been

successfully serving our client with cost-effective solutions. As a

renowned manufacturer and exporter, we offer qualitative range of

products, which includes S. G. Iron Castings In Various Grade. As an ISO

9001:2000 certified company, we conduct our manufacturing process

according to various national as well as international standards to

ensure a zero defect product range.

Our

teams of

qualified and trained professionals, who have extensive knowledge in

manufacturing different types of castings, With their dedicated and

passionate efforts, we are able to develop our assortment as per the

international standards.

Product Range

We offer a

wide range of Castings, which are extensively used in engineering &

Automobile Industries. Some of products are as follows:

- S. G. Iron Castings In Grade: 400/12, 500/7, 600/3, 700/2. And Equivalent Grade In Ductile Iron Includes Crank Shaft, Connecting Rod, Cam Shaft, Diff. Case, Brake Discs, Wheel, Lever, Hub, Gear Carrier and Cover.

Quality Assurance

An ISO

9001:2000 certified company; Monark Steels is committed to offer only

the best quality of S.G. Iron Casting, Steel Casting, SS Casting and

others to its clients, at competitive price. As a part of our endeavor

to fulfill this commitment, we follow a quality policy within our

organization. In addition, our quality controllers ensure that we use

only the best quality raw materials in the production processes.

Furthermore, they test our final product with following equipment:

- Spectrometer to analyze the chemical composion of the metal

- Carbon Equivalent Meter to Analyze Carbon and Silicon before pouring Metal

- Temperature Measuring Instrument

- Hardness testing machine

- UTS ,Ultrasonic, Radiography available near by..

- Molding Sand Testing -

- 1.Green Compressive Strength Machine

- 2.Moisture Tester

- 3.Permeability Meter

- 4.Compactability

- 5.Sieve Analyzer

- 6.Mold Hardness Tester.

Manufacturing Unit

We posses a

sound manufacturing unit, which is facilitated with latest fabrication

and designing equipment to carry out different manufacturing processes

including:

- Melting

- Molding

- Sand Plant

- Metallurgical Laboratory Testing

- Out Sourcing Facilities

- Heat Treatment

- Casting Cleaning

- Machinery Facility

- Induction Furnace -300kg capacity

- ARFA 300 Molding machine (box size-20in x 20 in)

- Heat Treatment Furnace – 1000 kg capacity

- Sand Intensive mixure – 250 kg

- Air Compressor

- Grinding Machine

- Shot Blasting Machine.

- Machine shop consist – CNC,VMC AND Convential machine like lathes milling and drilling machines.

GST : 27AACFM1681K1Z4

|

|

|

|

MONARK STEELS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |